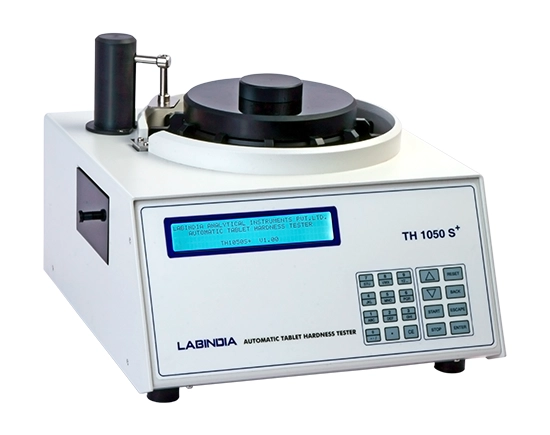

Hardness Tester TH 1050 S+

This hardness tester is equipped with user-interactive software in dialogue mode which enables in the ease of operation as well as it provides protection against invalid entries. The design of the Hardness Tester TH 1050 S+ allows it to perform a continuous automatic run of up to 1-100 tablets and it simultaneously measures the different parameter of the tablets. Armed with a linear displacement method, the user can select the speed from 0.4 to 3.2 mm/sec of this tablet hardness tester.

Fast advance and return movement saves time.Plus/minus Tolerance Limit for Pass/Fail criteria with Star mark for out of limit values.

- Advance Micro-controller based user-friendly state-of-the-art product design with alphanumeric splash waterproof polyester soft keys for keyboard.

- user interactive software in dialogue mode for ease of operation with protection against invalid entries.

- 4 Line X 40 char Wide Display with white backlight.

- 12 Position Carousal for Automatic transfer of tablet to measurement location. Simultaneous measurement of parameter - Thickness, Length/Diameter, Weight, Width & Hardness. Facility for Width measurement and Automatic Tablet Weight transfer.

- The built in Sweeper blades for removal of broken pieces, debris & dust from the tablet path.

- Groove for better positioning oblong shape sample tablets.

- Non-Volatile memory storage - 99 methods/ recipes having parameters with easy scroll.

- Alphanumeric entries of Sample Name and Identification/Batch Number for authentication.

- Automatic run can be performed continuously up to 1-100 tablets. Run can be restarted in case of interruption due to power failure.

- Linear Displacement Method with selectable speed 0.4 to 3.2mm/sec

- Fast Advance and Return movement of breaking arm saves test run time.

- Daily Auto Incremented Run Number for authentication of each test run.

- Factory entered CUSTOMER NAME & Instrument Serial Number on Print report data -makes system foolproof and GLP compliant.

- Two Tier - a) ADMIN, and b) USER password protection for method editing and Validation. 50 Users can be set with Name and password.

- Built-in Real Time Clock (RTC) for date and time display and on printout.

- Result resolution - 0.1N & 0.01mm as per unit selected.

- Process Stage, Compression Press no. entry & Comment for additional information

- Plus/minus Tolerance Limit for Pass/Fail criteria with Star mark for out of limit values.

- Built-in Validation/Calibration protocol with verification for Hardness as per USP requirements - 3 point Load Cell calibration with Standard weights, Length/Diameter and 3 point Thickness Calibration with Standard thickness gauges.

- Quick RUN for Width, Thickness, Length & Hardness or all parameter measurement in sequence up to 100 sample tablets with GLP information.

- Error indication on display helps user to trace the problem.

- Printer Compatibility for Deskjet, Inkjet & Dot-matrix printer.

- PC Based Data downloading facility using EDC 21 software over LAN (optional)

|

Control |

Micro-controller based (Advanced version of microprocessor) |

|

Keyboard |

Alphanumeric splash waterproof polyester soft keys. |

|

Display |

40 x 4 line back lighted liquid crystal display (LCD) |

|

Test Parameter |

No. of Tablets = 1 - 100. |

|

1. Thickness |

• Measuring Sensor - Linear Transducer • Measuring Range - 0.1mm to 15.0mm. • Measuring Unit - mm or inch. • Measuring Accuracy - Better than ± 0.06mm. |

|

2.Width (in Separate Mode) |

• Measuring Sensor - Stepper controlled Load Touch sensed • Measuring Range - 0.5mm to 15.0mm • Measuring Unit - mm or inch • Measuring Accuracy - Better than ± 0.06mm. |

|

3. Diameter/Length |

• Measuring Sensor - Stepper controlled Load Touch sensed • Measuring Range - Diameter 0.5mm to 25.0mm Length 0.1mm to 32.0mm • Measuring Unit - mm or inch. • Measuring Accuracy - Better than ± 0.06mm. |

|

4. Hardness: Speed Control by Stepper motor |

Linear Displacement Range 0.4, 0.8, 1.2, 1.6, 2.0, 2.4, 2.8, 3.2 mm/sec with fast advance and return of breaking arm. • Measuring Sensor - Load Cell - Strain gauge • Measuring Range - 2N to 500 N. (600N - Optional) • Measuring Unit - N (Newton’s), Kp (Kilo Ponds), Kgf Sc (Strong Cobb), Lbs / Pound. • Measuring Accuracy - ± 1N / ± 0.1 KP |

|

5. Weight: |

• Manual Entry by User (for repor ting purpose) • Automatic Balance Inter face - Sartorius / Mettler when Automatic Wt. Transfer option is selected. |

|

Method Storage |

99 programs with parameters |

|

Data Storage |

Available with Non-Volatile memory. |

|

Report Format |

a) GLP & Pharmacopoeia compliant repor t with Statistics (Avg, Min, Max and RSD) b) Program parameter Report. c) Validation Reports |

|

Output |

a) Centronics parallel por t for Dot matrix / Desk jet Printer. b) RS232 C por ts for i) Balance connectivity (Sar torius/Mettler) ii) PC Connectivity for Data Download |

|

Instrument weight |

15 kgs |

|

Dimensions |

340W x 270H x 380D mm. |

|

Power |

110 / 230Vac, ± 10%, 60 / 50 Hz, 50W. option available. |

|

Environmental Operating Conditions |

a) Operation: Indoor. b) Temperature: Ambient to 45°C. c) Humidity: 5 to 90% non-condensing. d) Altitude: Upto 2000m |